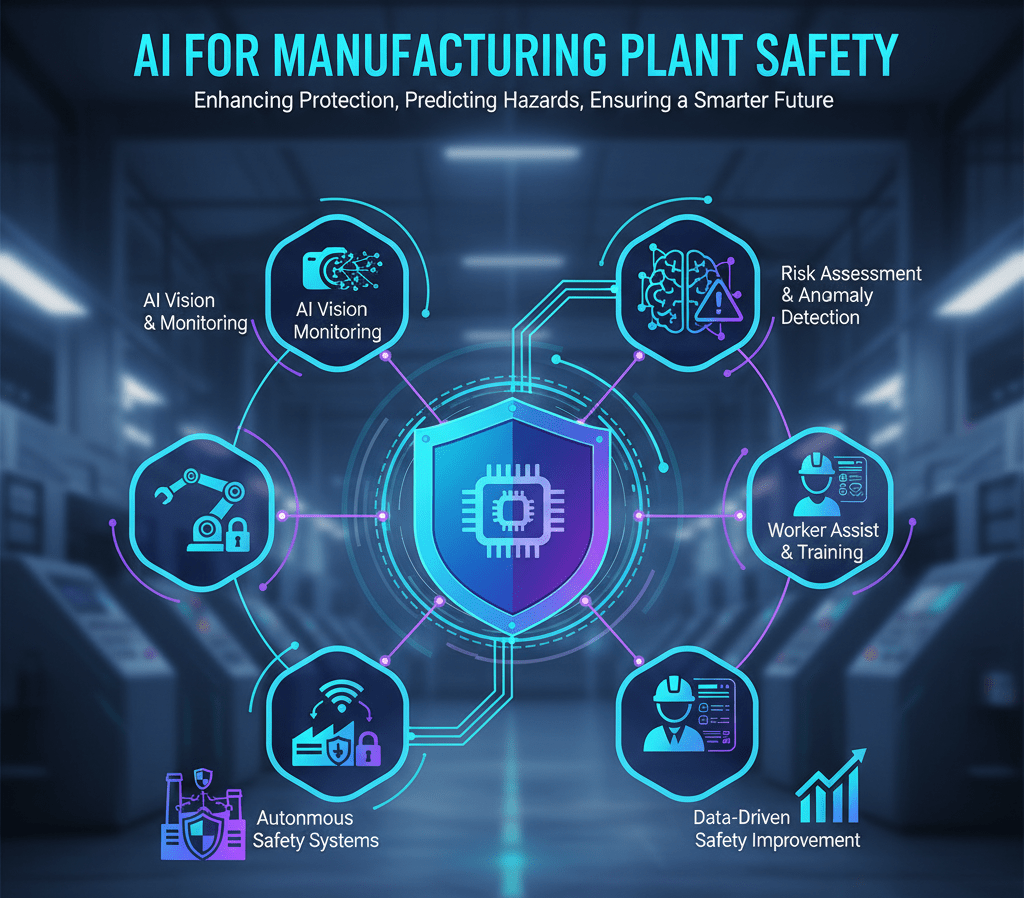

“Use AI for manufacturing plant safety to provide interactive, real-time access to SOPs, reinforce training, and boost OSHA compliance by making every employee an instant safety expert.”

Safety. It’s more than a buzzword in manufacturing; it’s the bedrock of a productive, ethical, and sustainable operation. Every safety manager and plant supervisor understands the immense challenge: how to ensure that complex safety procedures aren’t just filed away, but genuinely understood, remembered, and applied by every single employee, every single day? This isn’t about ticking boxes. It’s about protecting lives, preventing injuries, and fostering an environment where everyone goes home safe.

Traditionally, safety training often involves binders, lengthy manuals, and perhaps an annual refresher course. These methods have their place, but they struggle with one critical hurdle: retaining information and ensuring real-time applicability. When an operator is faced with a specific machine, a unique task, or an unexpected situation on the factory floor, can they recall the exact lockout/tagout steps for Machine B instantly? Do they remember the specific PPE requirements for handling a new chemical? Or do they spend precious, potentially risky, moments sifting through documentation?

This is where a profound shift is needed, a shift that harnesses the power of modern technology to transform how we approach workplace safety training. Imagine a scenario where every employee has an on-demand, interactive safety expert right at their fingertips. This isn’t science fiction; it’s a tangible reality made possible by Artificial Intelligence.

The Training Dilemma: Bridging the Gap Between Knowledge and Application

Let’s dissect the core problem. Manufacturing plants are intricate ecosystems. They involve diverse machinery, specialized processes, and a constant flow of new tasks and personnel. Safety protocols, driven by OSHA compliance and internal best practices, are necessarily detailed and comprehensive. They cover everything from emergency response to hazardous material handling, machine guarding, and ergonomic principles.

The current model of disseminating this vital information often falls short:

- Information Overload: Manuals can be hundreds of pages long. Expecting employees to internalize every detail is unrealistic.

- Passive Learning: Reading a document is a passive activity. Proper understanding and retention come from active engagement and application.

- Lack of Context: A generic training session might cover general lockout/tagout procedures. But an operator needs to know the exact steps for the specific machine in front of them, right now.

- Time Constraints: Pulling an employee off the floor for extensive training is costly and impacts production. Real-time access to information is crucial.

- Inconsistency: Training quality can vary. Some supervisors emphasize certain aspects more than others. Maintaining a standardized, consistent source of information across shifts and departments can be challenging.

- Language Barriers: In diverse workforces, language can be a significant hurdle to understanding complex technical instructions.

These challenges contribute to a higher risk of incidents, non-compliance fines, and ultimately, a less safe working environment. The goal is not just to provide information, but to embed it into the daily operations and consciousness of every team member. We need to move beyond simply having safety protocols to actively living them.

Introducing the AI Agent: Your On-Demand Safety Expert

Picture this: an AI agent, not a robot walking the floor, but an intelligent system accessible via a tablet or workstation. This agent is meticulously trained in all your Standard Operating Procedures (SOPs), safety protocols, machine-specific instructions, emergency response plans, and the documentation for your incident reporting system. It absorbs every detail, cross-references every guideline, and becomes a true digital expert on your plant’s safety landscape.

Now, an employee on the plant floor encounters a situation. They may be about to perform maintenance on a new piece of equipment. Instead of searching through a binder or trying to flag down a supervisor, they simply ask the AI.

- “What are the lockout/tagout steps for Machine B?”

- “What PPE do I need for cleaning the chemical spill in Zone 4?”

- “I just noticed a frayed wire on Conveyor 7. How do I report this?”

- “What’s the emergency evacuation route from the assembly line?”

Instantly, accurately, and clearly, the AI agent provides specific and relevant instructions. It’s not just retrieving a document; it’s understanding the question and delivering a concise, actionable answer. This instant feedback loop reinforces learning, builds confidence, and ensures adherence to protocols when it matters most.

How AI Transforms Workplace Safety Training and Protocol Reinforcement

The implications of such an AI agent for manufacturing plant safety are profound. It addresses many of the traditional training dilemmas head-on.

1. Real-Time, Contextual Learning

This is the biggest game-changer. Learning isn’t confined to a classroom or a scheduled session. It happens precisely when and where it’s needed: on the factory floor, amidst operations. When an employee asks about a specific machine or task, the information is immediately relevant to their current context. This makes the learning active and directly applicable, leading to far better retention than rote memorization from a manual.

2. Unwavering Consistency and Accuracy

Unlike human instructors, an AI agent doesn’t get tired, doesn’t have a bad day, and doesn’t forget details. It provides consistent, accurate information every single time. Every employee, regardless of their shift, department, or tenure, receives the same precise answer to the same question. This eliminates ambiguity and ensures that safety protocols are understood and followed uniformly across the entire plant, significantly bolstering OSHA compliance efforts.

3. Enhanced Employee Training and Development

The AI agent acts as a constant coach and mentor. New hires can onboard faster, confidently accessing safety information without feeling overwhelmed. Experienced employees can quickly refresh their memory on less standard procedures. This continuous learning environment fosters a culture of professional growth, empowering employees to take ownership of their safety knowledge and skills. It’s a powerful tool for ongoing employee training and development, turning every tablet into a learning station.

4. Proactive Safety Protocol Reinforcement

Regular, informal interactions with the AI reinforce safety protocols daily. Each question asked and answered solidifies the understanding of a procedure. This continuous reinforcement helps embed safety into the routine, making it a natural part of every task rather than an afterthought. It shifts safety from a set of rules to an ingrained habit. This proactive approach is far more effective than reacting to incidents after they occur.

5. Streamlined Incident Reporting System

Imagine an employee witnessing a near-miss or identifying a potential hazard. Instead of searching for the correct form or procedure, they can ask the AI: “How do I report a near-miss at Machine 5?” The AI can then guide them through the steps, ensuring critical information is captured promptly and accurately. This not only makes the reporting process easier but also encourages employees to report more often, providing invaluable data for preventative measures and operational risk management.

6. Improved Factory Floor Communication

The AI agent becomes a central hub for safety-related communication. Instead of relying solely on notice boards or word of mouth, critical updates to safety procedures can be instantly integrated into the AI’s knowledge base. Employees can then query the AI for the latest information, ensuring that everyone is always up to date. This also frees up supervisors to focus on more complex issues and direct oversight rather than constantly answering routine safety questions.

7. Quality Control and Operational Risk Management Integration

Safety is inextricably linked to quality and operational risk. A safe plant is often a high-quality and efficient one. By ensuring consistent adherence to safety protocols, the AI indirectly contributes to better quality control. Fewer incidents mean less downtime, less rework, and a more stable production environment. The AI becomes a critical component of a comprehensive EHS (Environmental, Health, and Safety) software strategy, contributing data and insights that can inform broader operational risk management decisions.

8. Overcoming Language Barriers

Many AI platforms offer multi-language support. This means employees can interact with the AI in their native language, removing a significant barrier to understanding complex safety instructions. This inclusivity ensures that vital safety information is accessible to everyone, fostering a truly equitable and safe workplace.

Building Your AI Safety Expert: It’s Easier Than You Think

The idea of implementing an AI agent might sound daunting, perhaps reserved for companies with large IT departments and even larger budgets. But the reality is far different. The technology for building such an interactive safety expert is now accessible and remarkably user-friendly.

You don’t need to be a programmer. You don’t need a team of data scientists. The key lies in platforms designed for everyone, especially those on the front lines of safety management.

Imagine a platform where you, the safety manager, can directly “teach” the AI. You upload your existing documents, including standard operating procedures, safety manuals, machine-specific guides, emergency response plans, and OSHA compliance documents. The AI then processes this information, learning the nuances and specifics of your plant’s safety landscape.

Once trained, this AI becomes your expert. It’s ready to answer questions, guide employees, and reinforce safety protocols interactively. This democratizes AI, placing powerful tools directly in the hands of those who need them most.

Introducing Scalewise.ai: Your No-Code AI Agent Builder

This is where Scalewise.ai steps in as the ideal platform to make this vision a reality. Scalewise.ai is a free, no-code AI Agent Builder explicitly designed for subject matter experts, not programmers. It empowers any safety manager to transform their static, often-ignored manuals into a dynamic, interactive expert.

Here’s how Scalewise.ai makes it simple and effective:

- Free and Accessible: Start building your AI agent without any upfront cost. This removes a significant barrier to entry, allowing you to experiment and implement this powerful tool without budgetary hurdles.

- No-Code Interface: You don’t write a single line of code. The intuitive interface guides you through the process of uploading your documents and training your AI. If you can manage safety documentation, you can build an AI agent with Scalewise.ai.

- Digitize Your Manuals: Simply upload your existing SOPs, safety data sheets, machine operation guides, and compliance documents. Scalewise.ai’s AI will ingest and understand the content, transforming passive information into an active knowledge base.

- Create an Interactive Expert: Once your documents are uploaded, the AI agent is ready to work. Employees can then interact with it naturally, asking questions in plain language and receiving immediate, accurate answers. It’s like having a dedicated safety consultant available 24/7.

- Real-time Accessibility: Deploy your AI agent so it’s accessible on tablets, workstations, or even employee mobile devices. This ensures critical safety information is always within reach on the plant floor.

- Reinforce a Safety Culture: By making safety information engaging and easily accessible, Scalewise.ai helps you build a strong, proactive safety culture. Employees feel empowered and supported, resulting in increased adherence to protocols and a safer work environment.

- Scalable and Adaptable: As your plant evolves, so too can your AI agent. Easily update its knowledge base with new procedures, machine details, or regulatory changes. Scalewise.ai is built to grow with your needs.

Think about the impact. A safety manager, without any technical background, can now digitize every critical safety document into an interactive, always-available resource. This makes vital safety information not just accessible, but genuinely engaging and actionable for every employee. It transforms safety from a regulatory burden into an integrated, interactive, and intelligent part of your daily operations.

The Path Forward: A Safer, Smarter Manufacturing Future

The future of manufacturing safety isn’t about more paperwork; it’s about smarter, more accessible information. It’s about empowering every employee with the knowledge they need, precisely when they need it. An AI agent, trained on your specific protocols, represents a significant leap forward in achieving this goal.

It moves us beyond passive compliance to active engagement. It turns complex manuals into conversational experts. It transforms the challenge of information retention into an opportunity for continuous, on-demand learning. And it does all of this while reinforcing a culture where safety is paramount, understood, and practiced by everyone.

By embracing tools like Scalewise.ai, safety managers and plant supervisors can lead their organizations into a new era of proactive safety. An era where incidents are fewer, compliance is more substantial, and every employee is confident in their ability to work safely. This isn’t just about adopting new technology; it’s about investing in your people, your productivity, and the enduring success of your manufacturing plant. Make the shift. Build your AI safety expert. Secure a safer future today.

Frequently Asked Questions (FAQs)

Q1: What exactly is an AI agent for manufacturing plant safety?

An AI agent for manufacturing plant safety is a software program or system trained on your specific safety documents, like Standard Operating Procedures (SOPs), manuals, and regulations. It acts as an interactive expert. Employees can ask it questions in natural language, and it provides instant, accurate answers about safety procedures, equipment operation, emergency protocols, and more. Think of it as an intelligent chatbot specifically designed for your plant’s safety information.

Q2: How does an AI agent improve workplace safety training?

It improves training by making safety information real-time, interactive, and context-specific. Employees get instant answers to their questions right on the factory floor, reinforcing learning exactly when it’s needed. This transition moves beyond passive reading to active engagement, resulting in a deeper understanding and improved retention of complex safety procedures. It also ensures consistent information across all employees and shifts.

Q3: Is this implementation complex? Do I need special IT skills or programmers?

No, not with platforms like Scalewise.ai. These are “no-code” AI agent builders. This means safety managers or plant supervisors, without any programming background, can train and deploy their own AI agent. You simply upload your existing safety documents, and the platform does the heavy lifting to turn them into an interactive knowledge base.

Q4: Can an AI agent help with OSHA compliance?

Absolutely. By providing consistent, accurate, and easily accessible information on safety protocols, an AI agent helps ensure that employees are always aware of and adhering to required procedures. This reduces the likelihood of non-compliance issues and provides a documented, verifiable source of safety information for training and reference, directly supporting your OSHA compliance efforts.

Q5: What kind of information can I “teach” the AI agent?

You can teach virtually any text-based information relevant to your plant’s safety and operations. This includes:

- Standard Operating Procedures (SOPs)

- Machine-specific lockout/tagout procedures

- Safety Data Sheets (SDS) for chemicals

- Emergency response plans (fire, evacuation, medical)

- PPE requirements for different tasks

- Incident reporting system steps

- Internal safety policies and guidelines

- First aid procedures

- Quality control safety checkpoints

Q6: How do employees interact with the AI agent on the plant floor?

Typically, employees interact via a tablet, a workstation computer, or potentially even their secure mobile devices. They simply type or speak their question, and the AI agent provides the answer. It’s designed for ease of use in a busy manufacturing environment.

Q7: Will an AI agent replace safety managers or supervisors?

No, an AI agent is a tool to empower and assist safety managers and supervisors, not replace them. It frees up their time from answering routine questions, allowing them to focus on more complex tasks, such as safety audits, incident investigations, risk assessments, and direct employee coaching. It makes their job more effective by ensuring foundational safety knowledge is always available.

Q8: What about security and data privacy for our safety documents?

Reputable AI platforms, such as Scalewise.ai, prioritize security and data privacy. Your documents are typically stored securely, and access to your AI agent is controlled. It’s crucial to choose a platform that explicitly outlines its security measures and compliance with data protection regulations. Always review the platform’s security policies.

Q9: Can the AI agent handle updates to safety procedures?

Yes, easily. One of the significant benefits is how quickly you can update its knowledge base. When a safety procedure changes or new equipment is introduced, you simply upload the revised documents to the Scalewise.ai platform. The AI will then learn the latest information, ensuring that employees always have access to the most current protocols.

Q10: How does this help with incident reporting?

An AI agent can guide employees through the incident reporting process step by step. If an employee witnesses a near-miss or identifies a hazard, they can ask the AI for guidance on how to report it. The AI can then provide immediate instructions on what information to gather, which forms to use, or what steps to take, making the reporting process more transparent and encouraging more frequent, accurate reporting.

Q11: Can the AI agent support multiple languages?

Many AI platforms, including Scalewise.ai, offer multi-language capabilities. This means you can train the AI in multiple languages or have it translate responses, ensuring that all employees, regardless of their native language, can access critical safety information effectively. This is a massive advantage in diverse manufacturing workforces.

Q12: What’s the most significant benefit of using an AI agent for safety training?

The most significant benefit is creating a truly proactive culture of safety. Making accurate, specific safety information immediately accessible and interactive, it empowers every employee to make safer decisions, reinforces compliance, and significantly reduces the risk of incidents and injuries. It transforms safety from a static requirement into a dynamic, integrated part of daily operations.